How Drone Technology Is Construction’s Eye in the Sky

The advent of drones has given the construction industry the opportunity to get a unique view of a building project as it rises from the ground

Drones – also known as unmanned aerial vehicles, or UAVs – vary in size and operability. Some are single-rotor machines, akin to a helicopter, but most are multi-rotor affairs, combining more than two rotors with fixed-pitch spinning blades, which generate lift. Multi-rotor drones often feature three, four, six or eight rotors; the greater the number of rotors, the heavier the load that can be carried. As well as cameras, some drones are able to carry payloads of up to 12kg (26lb).

How can drones be used in construction?

Robotics, advanced technologies and modern methods of construction are all becoming increasingly important to a construction industry that needs to improve its productivity and data collection while also staying on top of its health and safety record. Yet some of these new technologies have not been embraced as much as many would like.

However, in recent years, the advent of drones in construction has been nothing short of a game-changer for the industry.

From monitoring the ongoing progress of a project to undertaking health and safety checks, drone-mounted cameras and data collection technology offer on-site contractors and office-based teams a previously unthinkable opportunity to see the state of play of a development.

Advantages and disadvantages of drones in construction

Improving safety, time and cost efficiency

The ability of a drone to access hard-to-reach places is a particular benefit to project teams, avoiding the need to use potentially dangerous ladders or complex scaffolding systems. It also removes the necessity of a person squeezing into narrow spaces to see the progress of work.

Additionally, in the hands of a skilled operator, a drone can map out a plot of land to determine its suitability for a particular project, locate and measure materials, identify hazards and ensure a site is secure from unwanted intrusion.

This is useful when assessing not only projects under construction but also existing buildings and infrastructure. For example, contracting giant Balfour Beatty worked with West Sussex County Council a few years ago, trialing the use of drones in a series of bridge inspections across the region.

According to Balfour Beatty, inspection work normally requires a degree of traffic management to allow inspectors to carry out works at height and over water safely. This inevitably creates disruption to the public and road users.

Steve Phillips, contract director for Balfour Beatty Living Places, said, “Using drones in our highways’ inspection work allows us to safely assess the work required, while dramatically reducing any potential hazards faced by our workforce who would traditionally carry out work such as bridge inspections at height.

“It’s a great example of how modern technology can be successfully used by industry.”

The use of drones also offered a financial boost; Balfour Beatty said the trials had saved around £8,000 ($10,170) compared with the cost of traditional inspections of such infrastructure.

While this does not sound like a particularly large sum, it offers some insight into the potential cost savings that could be made if the technology were to be rolled across a series of similar inspections on a wider scale.

Ongoing challenges and limitations

The advantages of using drones in construction are clear. Savings can be made, both in time and money. Site safety can be monitored and improved. Data collection can be better, as can an overview – literally – of the work being carried out. But there are downsides.

As with many potentially hazardous activities, complex paperwork is required to cover the legal and liability sides of things when operating a drone.

Like all those who fly drones weighing more than 250 grams (0.55 pounds) in the UK, Balfour Beatty’s drone pilots are licensed by the country’s Civil Aviation Authority (CAA). Drone pilots need to pass a theory test and gain flying identification, while companies operating drones also need to register with the CAA.

The European Union demands similar compliance for operating UAVs across its territories.

In the US, the Federal Aviation Administration (FAA) regulates the use of drones and spells out a series of limitations, including flying a drone at a maximum altitude of 400 feet.

There is also an FAA requirement to “maintain a visual line of sight with the drone at all times. Violating these rules can result in significant fines or even criminal charges,” according to a paper published by a research team hailing from the Department of Civil Engineering at Kyungpook National University and the Daegu Urban Development Corporation, both in South Korea.

There are other potential pitfalls. The performance of a drone is dependent on the weather. Unless fitted with stabilizing technology, many don’t fly well – and therefore are unable to transmit data appropriately – in windy conditions, while the size of a drone’s power unit necessarily limits how long it can be in the air.

And as with any technology involved in the collection and transmission of data, there is the potential for a data breach through hacking activity or equipment failure.

A bright future for drone use in the construction industry

But while these challenges are a constant presence, the future for drones in construction looks positive.

The Korean research team mentioned above suggests the development of drones will encompass the development of more advanced sensors and imaging technologies.

“This could include sensors that can detect temperature changes or identify different types of materials more accurately, as well as imaging technologies that can provide more detailed and accurate images of construction sites,” it says.

The researchers add that the use of machine learning and artificial intelligence offers potential for future research in this area, not least through analysis of collected data where “patterns and trends that might be difficult for human inspectors to detect.”

This is undoubtedly encouraging. For an industry struggling with productivity, where a large project often takes 20% longer to complete than its original schedule had suggested and budgets similarly tend to inflate, the potential gains to be had from increased use of drones in construction will surely prove too good to pass up.

Share this post on:

Subscribe now

to receive newsletter with latest news weekly from Revu Experts Vietnam.

Related posts

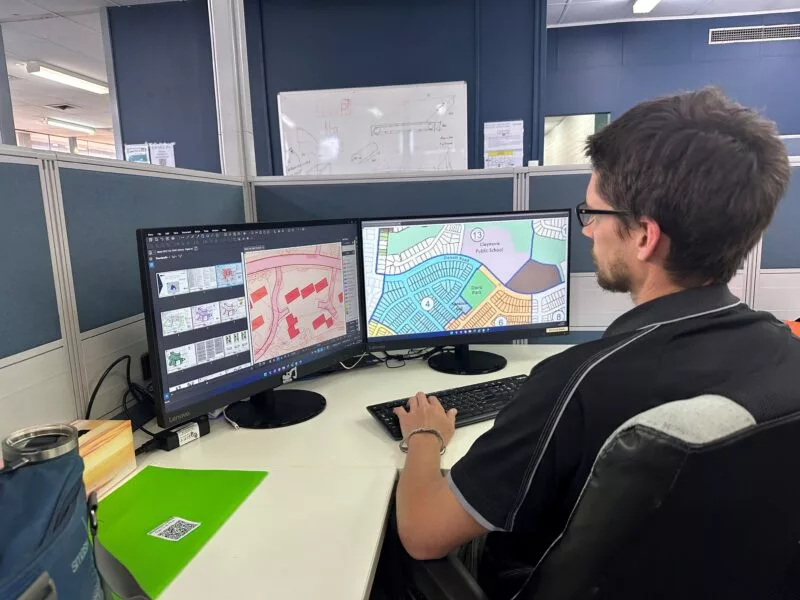

Musselman & Hall Boosts Efficiency with Bluebeam

Musselman & Hall has embraced Bluebeam software to streamline their project takeoff and management processes.

The Top 3 Most Effective Construction Project Management Software

Let’s explore the top 3 most effective project management software currently shaping the complex landscape of the construction industry.

How Bluebeam Revu’s Tool Chests Empower Civil Construction Companies

Explore how Bluebeam Revu’s Tool Chests contribute to the transformation of civil construction practices at Devcon Civil. Learn about the reasons behind Devcon’s investment in Bluebeam Revu and how it has elevated their project delivery capabilities.

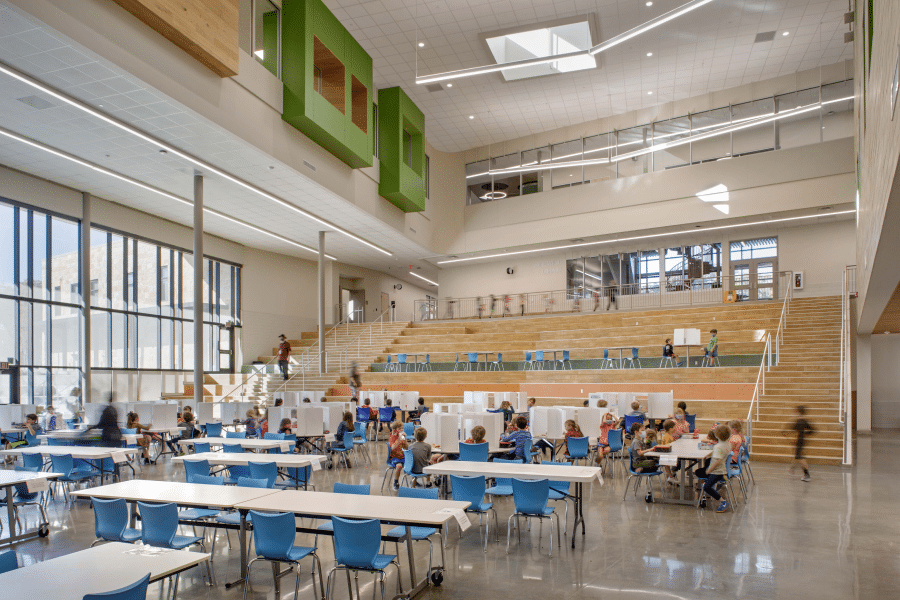

How AECOM Fast-Tracked Project Efficiency with Bluebeam

How AECOM Fast-Tracked Project Efficiency with Bluebeam AECOM turned to Bluebeam to streamline communication and efficiency on multiple aspects of the building and modernization of